|

|

#1

|

|||

|

|||

|

GE 1955 Intro to PC Boards

I recently picked up some GE service manuals from the 1950's, and one was introducing their M chassis, which was their first portable metal cabinet tv. It was apparently also their first set with PC boards.

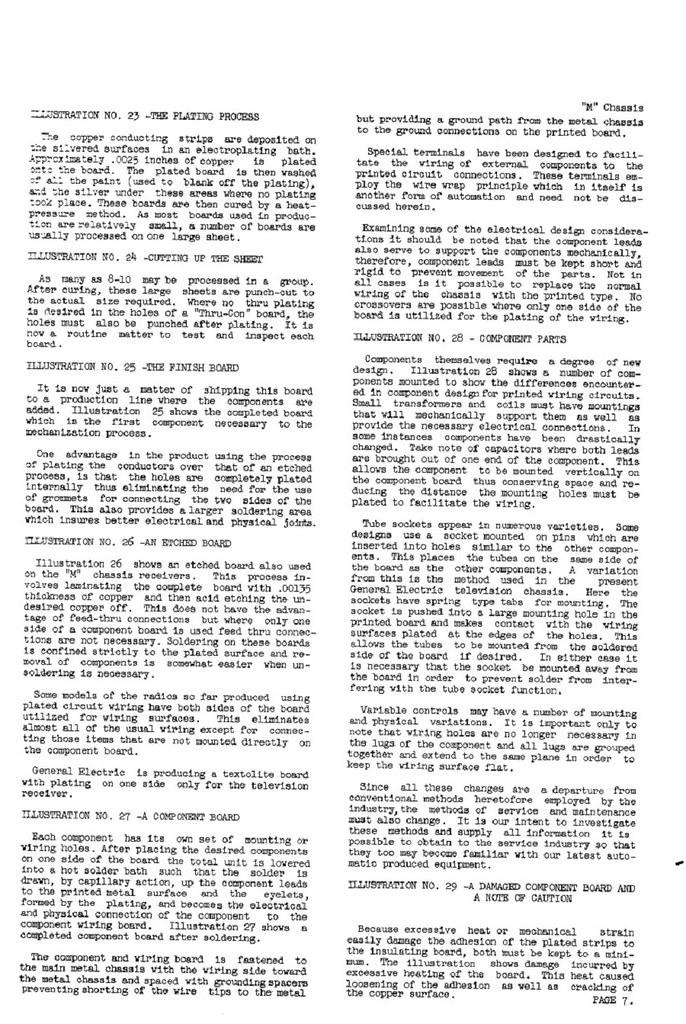

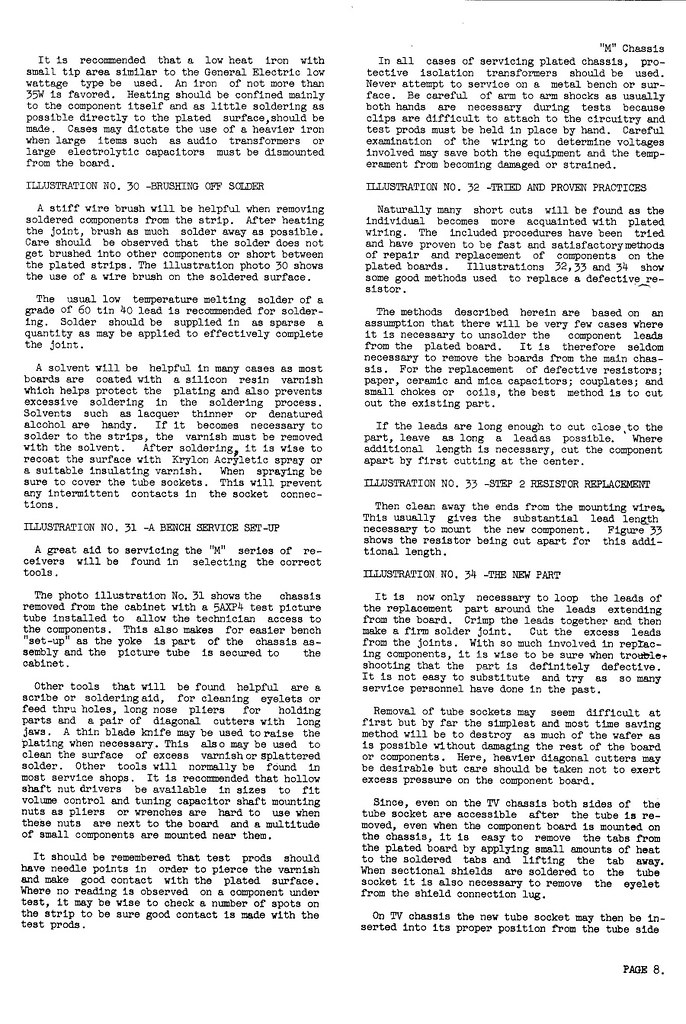

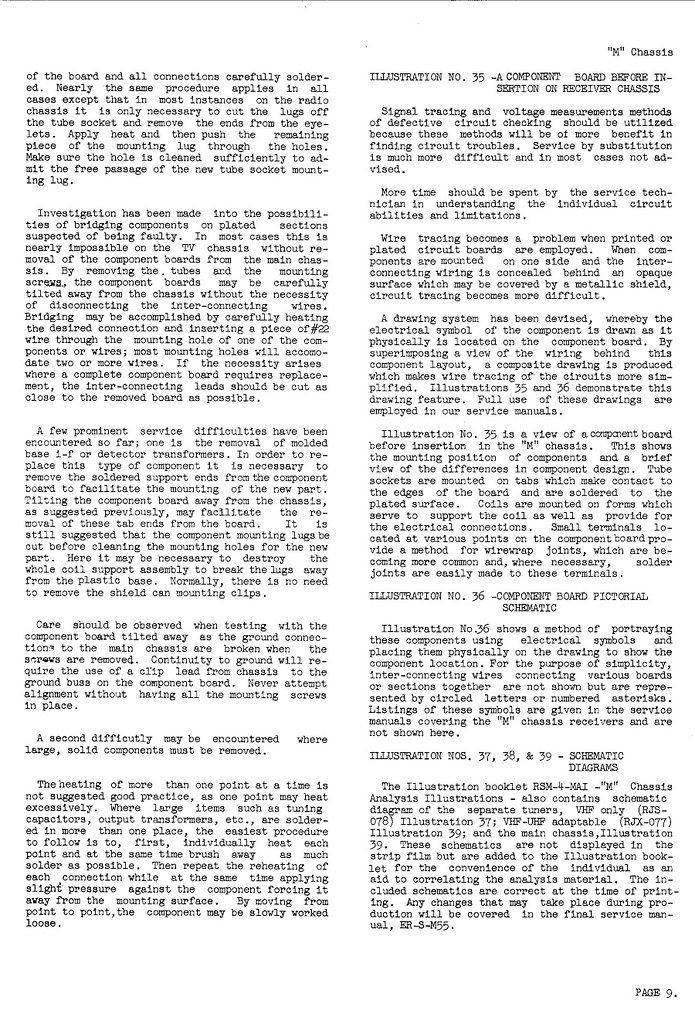

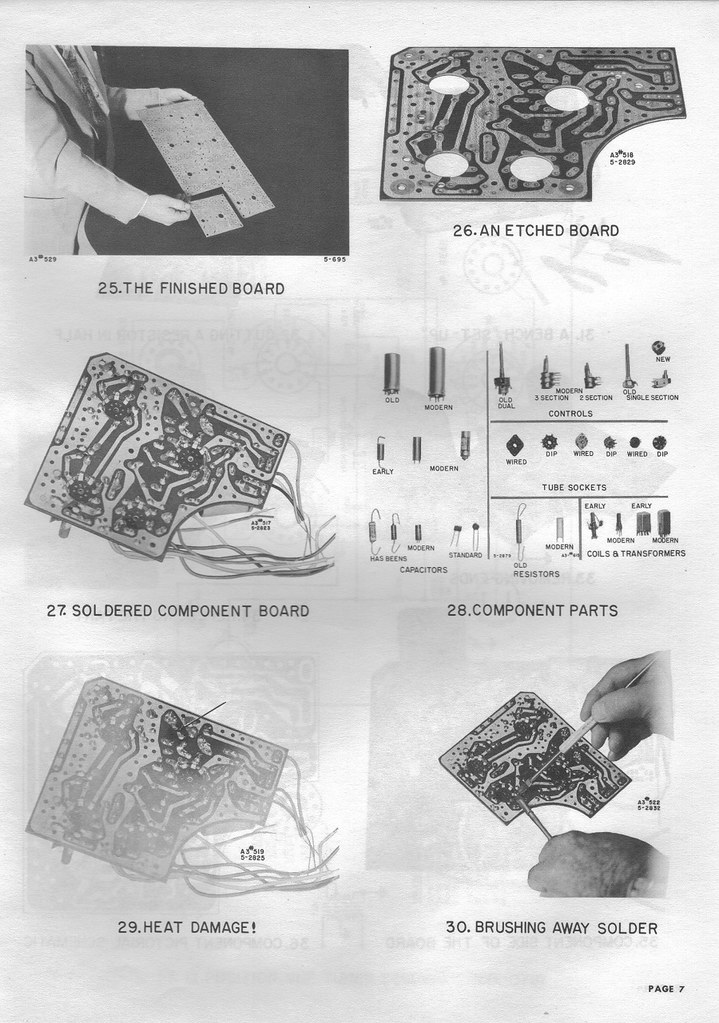

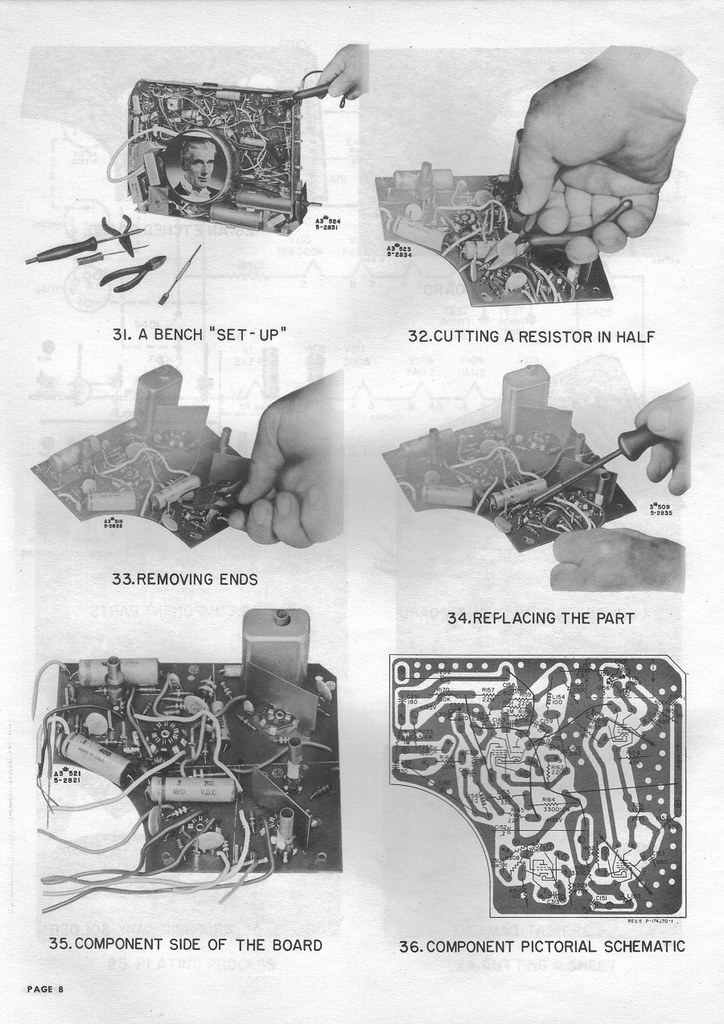

These are pages made from a slide presentation for techs, that were printed and sent out to dealers. The script goes with each of the pictures. The discussion of PC boards starts with Illustration 21. Two things that caught my attention: First, GE used both plated and etched boards. However, they admit the plated boards were superior. Second, instead of unsoldering leads to replace a part, they show cutting it out from the top and using the old leads as mounting posts for the new component. I know this isn't considered good practice today, but why? Would this be more acceptable with an older PC board that is at risk of damage if unsoldered? At any rate, these are a reminder of a time when PC boards were new technology and had to be explained to people.

|

|

#2

|

|||

|

|||

|

I wonder if Motorola held the patents on the plated circuit board? They came out with them, about three years earlier.

Admiral's etched boards, came out about a year later. Regarding component replacement, I could never see doing it the way they recommended. By the time you clipped the old component out and reheated the leads to solder in the new, the leads were loosened up, in the original solder dip. |

|

#3

|

||||

|

||||

|

I think I have some of those portables...

__________________

Tom C. Zenith: The quality stays in EVEN after the name falls off! What I want. --> http://www.videokarma.org/showpost.p...62&postcount=4 |

|

#4

|

|||

|

|||

|

I've had several of those as well. They really weren't high performance.

Very minimal AGC. You always had to readjust the contrast, when switching from low to high band channels. The local distance switch was a joke. It stayed in the distance position all the time.  The later production sets were a little better, as the horizontal AFC was troublesome in the early sets. |

|

#5

|

||||

|

||||

|

What attention to quality there was back then...looks like a very labor-intensive process(not to mention all of the precious materials required)..all to produce a mediocre set

I once found a Hotpoint-brand 50s tv at the curb and it had boards that looked just like this. It had sound and tuner but no video after the detector. I recall trying to probe the circuitry and the traces were beginning to lift. It appeared to be a victim of "running as hot as an oven"...tubes on pcb's is rarely a good build! I once found a Hotpoint-brand 50s tv at the curb and it had boards that looked just like this. It had sound and tuner but no video after the detector. I recall trying to probe the circuitry and the traces were beginning to lift. It appeared to be a victim of "running as hot as an oven"...tubes on pcb's is rarely a good build!

|

| Audiokarma |

|

#6

|

||||

|

||||

|

I repaired an AM/FM Westinghouse a while back with a PC board that was badly warped on one side. The audio output tube had been replaced at some time, and whoever done it didn't get the board slid in the cabinet back correctly. The heat of the tube cooking a board that was uneven permanently warped it.

Like the poster said above, "tubes on pcb's is rarely a good build". |

|

#7

|

|||

|

|||

|

I have some cute little pieces of solder shaped like springs that you slide over the old part stub and the new part lead to do the soldering. I have never used them but they should make it a little easier.

I suspect the reason for suggesting not desoldering a part is to avoid overheating the board. An Admiral table radio of the early 1960s used the 'new' circuit boards. To alleviate consumer concerns, the warranty said that the board was warranted for a lifetime. However, the warranty did not cover the parts on the board nor the labor. While anyone with a bit of understanding could see through that, it was obvious they were scamming. The cost of the board is trivial compared to the other costs. It gave new support for the idea that the big companies are NOT out for your good. |

|

|

|