My finishing materials showed up yesterday. I'm only posting this to provide information about an available product that solved a finishing dilemma for me. The wonderful advantages in quality and ease of application of nitrocellulose are, for me, more than offset by the issues around its use. I have a dedicated spray booth I use for spraying finishes on my guitars but it is not vented to the outdoors. It is a particulate filter and doesn't address the solvent fumes that come with spraying traditional lacquers. Besides quick drying and the grain enhancing characteristics of nitro, it has what's called "burn in" meaning each coat sprayed on melts the previous coats and becomes one solid finish. Shellac does this too but if you need to spray water based finishes like I do, burn in isn't a property they have had. It's an issue for any finish that gets wet sanded and rubbed out to a high gloss because when multiple, individual layers of a finish are sanded through, the layers show in the form of "witness marks".

About 10-15 years ago, due primarily to tightening VOC restrictions, waterborne finish manufacturers started to step up their game. The finishes got clearer, harder and popped grain better but they still went on a surface as distinct layers. Some products claimed burn it if recoated during a limited window but I found none of them satisfactory,

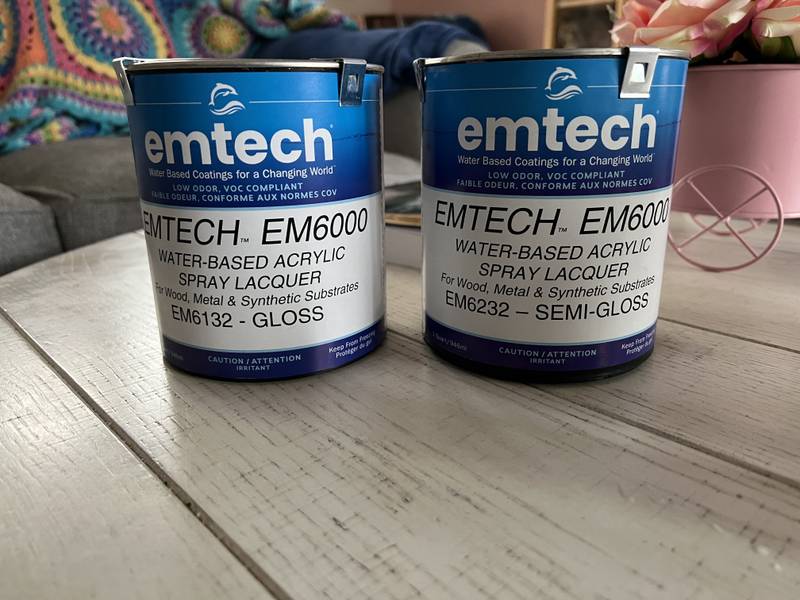

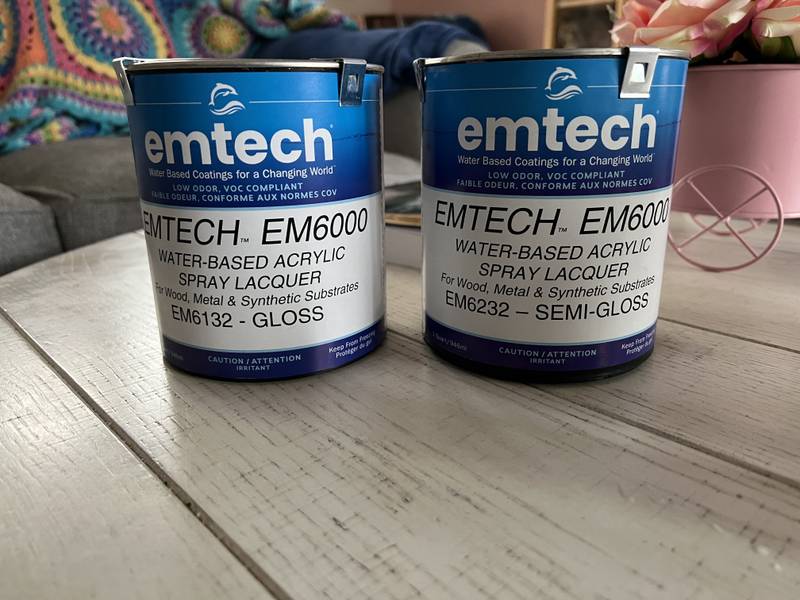

Target Coatings was a small startup company around this time and they developed a line of waterborne finishes including a lacquer claiming burn in if recoated within 48 hours, a time window considerably longer than the open recoat time for products like Resisthane, another claimant of burn in and water based. I tried their product line and I have never used anything else since. Their custom formula EM 6000 product is as close to nitrocellulose as you can get in a low VOC product. It is amazing. It cures rock hard, clear and has 100% burn in.

I only mention this because I struggled with finishing schedules, solvent fumes and other issues for years. This single product solved all of that. Every bit as good as nitrocellulose with the same properties but no solvents. It can be sprayed indoors with little concern. Of course, you need spray equipment. It's not a finish in a can. HVLP, self contained units are available. Instead of a compressor, they essentially use a fan to provide air flow and they are very good for spraying water based finishes.